Title: Review of solution growth techniques for 4H-SiC single crystal

DOI: https://doi.org/10.1007/s41230-023-2103-9

Author: Gang-qiang Liang, Hao Qian, Yi-lin Su, Lin Shi, Qiang Li, and *Yuan Liu

*Yuan Liu

E-mail: yuanliu@mail.tsinghua.edu.cn

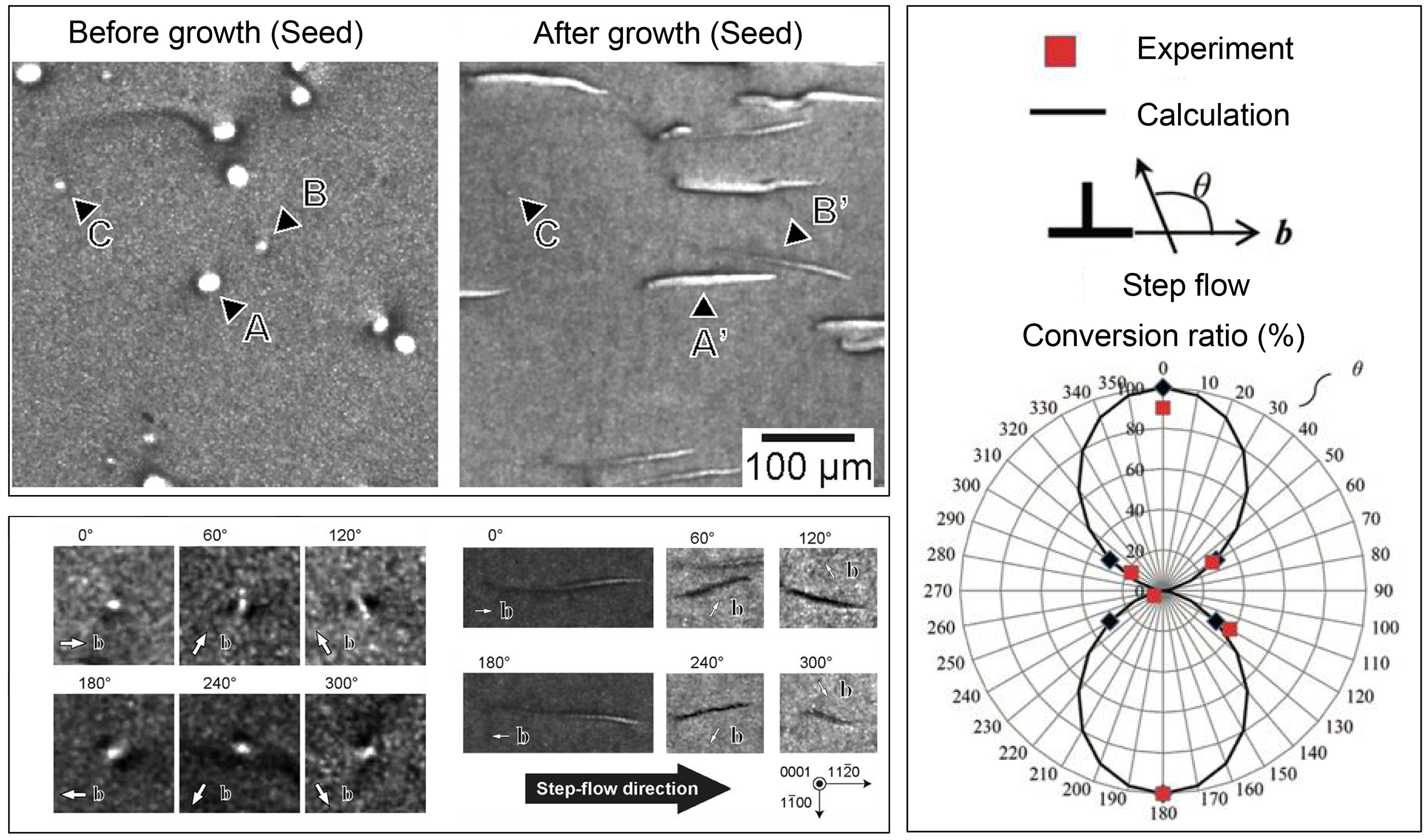

Abstract: Silicon carbide (SiC), a group IV compound and wide-bandgap semiconductor for high-power, high-frequency and high-temperature devices, demonstrates excellent inherent properties for power devices and specialized high-end markets. Solution growth is thermodynamically favorable for producing SiC single crystal ingots with ultra-low dislocation density as the crystallization is driven by the supersaturation of carbon dissolved in Si-metal solvents. Meanwhile, solution growth is conducive to the growth of both N- and P-type SiC, with doping concentrations ranging from 1014 to 1019 cm−3. To date, 4-inch 4H-SiC substrates with a thickness of 15 mm produced by solution growth have been unveiled, while substrates of 6 inches and above are still under development. Based on top-seeded solution growth (TSSG), several growth techniques have been developed including solution growth on a concave surface (SGCS), melt-back, accelerated crucible rotation technique (ACRT), two-step growth, and facet growth. Multi-parameters of the solution growth including meniscus, solvent design, flow control, dislocation conversion, facet growth, and structures of graphite components make high-quality single crystal growth possible. In this paper, the solution growth techniques and corresponding parameters involved in SiC bulk growth were reviewed.

Free full text: https://link.springer.com/article/10.1007/s41230-023-2103-9

If you'd like to learn more, please get it free at the following website:

https://www.springer.com/journal/41230 or

http://www.foundryworld.com/en/indexzhong.php/zazhishe/chinaguokan/type/3

Scan the QR code to download the papers published by China Foundry journal from 2020 to 2024